The Single Side Matte DTF film thickness should be 75u, with good temperature resistance and is not prone to deformation and suitable for many printers

The Single Side Matte DTF film thickness should be 75u, with good temperature resistance and is not prone to deformation and suitable for many printers

Hi Rubbing Single Matte DTF Film

Product Describtion

The Single Side Matte DTF film is a new DTF film product launched by our company. The advantage of this product is to increase the friction of single-sided matte DTF film. The previous way to solve the friction was to make DTF film double-sided dumb. For single-sided dumb film, we can also achieve high friction, which solves the problem that DTF film is easy to slide during the printing process.

Product Features and Benefits

1. Strong dtf ink absorption 2. The coating is uniform 3. Easy to peel off

4. high transfer rate excellent color brilliance 5. suitable for many printers 6. smooth surface

Code No. | CT-SM30 CT-SM60 CT-SM120 |

Color | Clear |

Main materials | PET film |

Effective thickness | 75um |

Item Size | 30cm * 100m 60cm * 100m 120cm * 100m A3 A4 Customize |

Suitable Printer : | Epson /HP inkjet printer |

Package | 4 Rolls/carton, 3.75kg/roll |

Suitable ink type | Water base pigment ink for DTF inkjet printing |

Tear off mode | cold tear |

Apparent effect | matte finishing |

Validity life | Under correct storage conditions , the film can be best used for 12 months. |

Storage | It must be stored in a clean , cool and dry place , the temperature is 5-30�� , the relative humidity is 40%-80%. |

Peel Off Easy to tear

Easy to separate and clean Difficult to separate and tear clean

Oil Return Easy to return oil

Easy to separate and clean Difficult to separate and tear clean

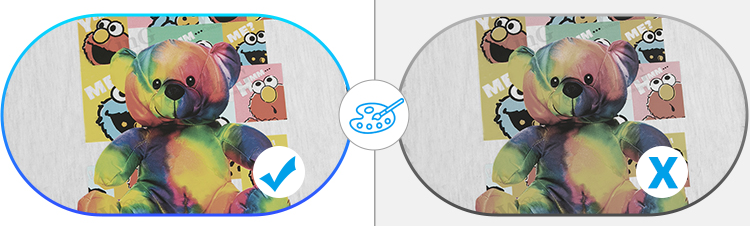

Chromatic aberration The color is not bright

excellent color brilliance Difficult to separate and tear clean

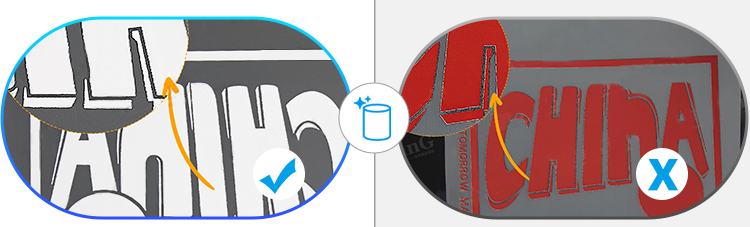

EDGE Unclear edge

There's no imaginary edge Visible shirt hem

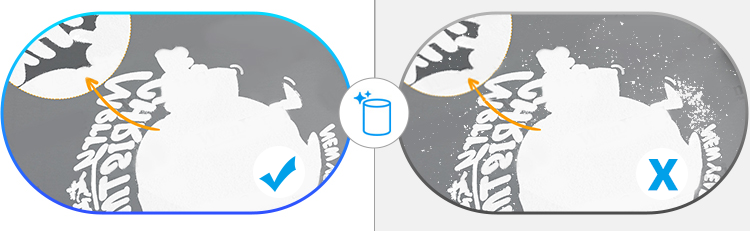

Sticky powder Serious powder sticking

There was no sign of sticky powder Obvious signs of sticky powder

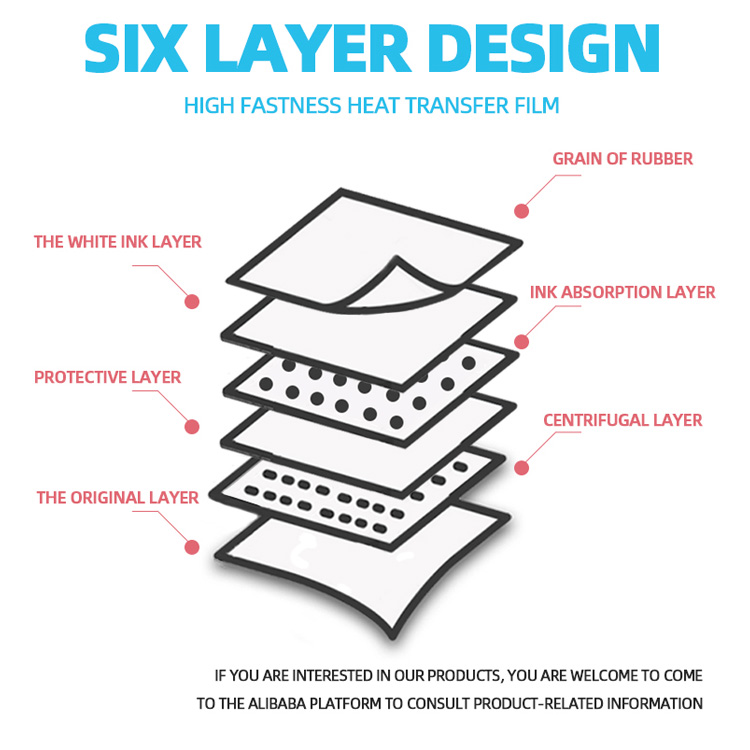

Cowint DTF Film 5-coating layer structure

Cowint's DTF film has a unique 5-layer structure. Generally, the DTF film of other companys have only two layers of coating: release layer and ink absorption layer. Our film has added a protective layer for ink dry and wet rubbing fastness and two ink absorption layers. In this way, our DTF film has the characteristics that the ink absorption performance during printing is much better than other companies. At the same time, it has high dry and wet rubbing fastness after transfer.

Application scenarios

In addition to its excellent color performance, DTF FILM can also be applied to a variety of high temperature resistant

fabric materials, such as socks, canvas shoes, hats, T-shirts, canvas bags and other commodities. Small studios

have the need to print a small amount of various peripheral products. The cheap price of offset heat press

(DTF direct-injection film printer)and the simple operation process can help these companies to print their own products.

Workshop show

DTF FILM has undergone three processes of coating, dispersion and drying.

Our process flow is as long as 40 meters, and the average factory is 25 meters.

The film coating is more uniform and the process is more stable;

Cowint has been a manufacturer of transfer paste for 27 years. All the raw materials of the coating

are developed by ourselves. We know the formula better, and we know the release degree of the film better.

We produce coating raw materials by ourselves, which can keep the quality stable and control the cost.

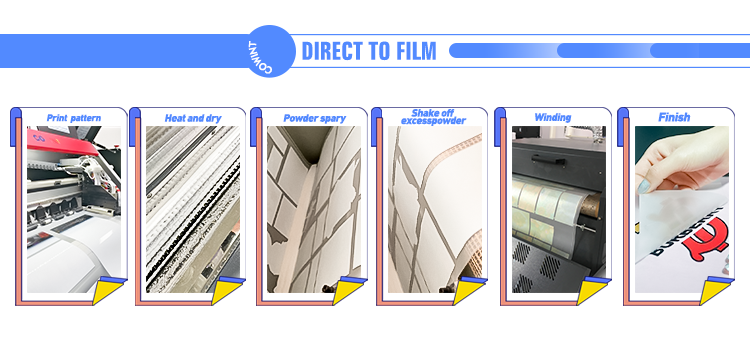

How To Use DTF film

1.Prepare the heat transfer membrane

2.Input the design drawing you want to print into the transfer machine for printing

3.The printed film is shaken evenly through the powder shaking machine

4.Evenly spread hot melt powder film through the press, the pattern printed on the clothes, about 10-15 seconds can be

5.And you're done

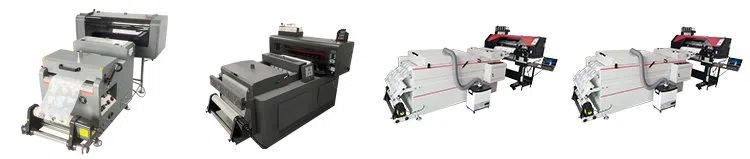

Suitable Printer

1.A1 Epson XP600 two head DTF printer

2.A3 Epson XP600 two head DTF printer

3.KW602 I3200 two head DTF printer

4. KW604 I3200 four head DTF printer

| A1-XP600 | A3-XP600 | KW-602 | KW-604 |

| 228.100.83CM | 170*70*76CM | 212.5*100.2*109.2CM | 275.6*100.2*108.1CM |

| EPSON-XP600 | EPSON-XP600 | EPSON-XP1080 | EPSON-i3200 |

| 135KG | 100KG | 375KG | 435KG |

| 600MM | 300MM | 600MM | 600MM |

| 4PASS\8㎡ 6PASS\6㎡ 8PASS\4㎡ | 4PASS\5㎡ 6PASS\3.5㎡ 8PASS\2㎡ | 4PASS\8㎡ 6PASS\6㎡ 8PASS\4㎡ | 4PASS\14.5㎡ 6PASS\10㎡ 8PASS\7㎡ |

HEAT TRANSFER FILM COLD TEAR.HOT TEAR | HEAT TRANSFER FILM COLD TEAR.HOT TEAR | HEAT TRANSFER FILM COLD TEAR.HOT TEAR | HEAT TRANSFER FILM COLD TEAR.HOT TEAR |

| MAINTOP PHOTOPRINT | MAINTOP PHOTOPRINT | MAINTOP PHOTOPRINT | MAINTOP PHOTOPRINT |

DTF FILM Four MajorTests

1. incoming inspection of raw materials

First of all, various tests are carried out on the raw materials, and every link of production must be subject to strict quality

inspection from production to delivery.

2. physical weather resistance test

To test the physical stability of the product after production, place the product in an oven at 70 degrees Celsius to bake

for 72 hours (no bean curd residue, no thinning, no deterioration.) This is to simulate the extreme weather encountered

by the product during shipping by sea , if the product does not deteriorate in this test, then the product is qualified.

3. product version making test

The cloth sample detection (tensile force, fastness, washing, wiping feel) is anti-sticky, which is the control

of the quality of the final product.

4.Environmental protection test

After the finished products are sent to SGS and INTERTEX and other testing institutions for environmental protection testing,

our products must obtain certificates such as GOTS/ZDHC/EX-POSSBO to meet the delivery requirements.

Environmental certificate

After the finished products are sent to SGS and INTERTEX and other testing institutions for environmental protection testing,

our products must obtain certificates such as GOTS/ZDHC/EX-POSSBO to meet the delivery requirements.

Unique advantages of Cowint

1. Top 10 brands, 27 years of history, with more industry experience;

2. Large capacity: glue 20,000 tons/year 2. Transfer film 15,000 rolls/month 3. Machine 500 sets/month (reflecting sales and strength)

3. It is a subsidiary of Zhongtian Group, covering an area of 18,000 square meters, with strong strength

4. All products are environmentally friendly and have environmental protection certificates (ECOPASSPORT / ZDHC L3/ GOTS/ SGS.....)

5. It is a 5-star merchant (Verified Five star Supplier, Printing ink chemical Area No.1 Brand) certified by Alibaba